Tudo que você precisa

A gama de elevadores de serviço ACADA é tão extensa que não tem igual no mercado. Guiados por corda, guiados por escada, com acionamento por cremalheira e pinhão, e cada versão está disponível em várias classes de desempenho e, sob solicitação, com acionamento a bateria (sem fio).

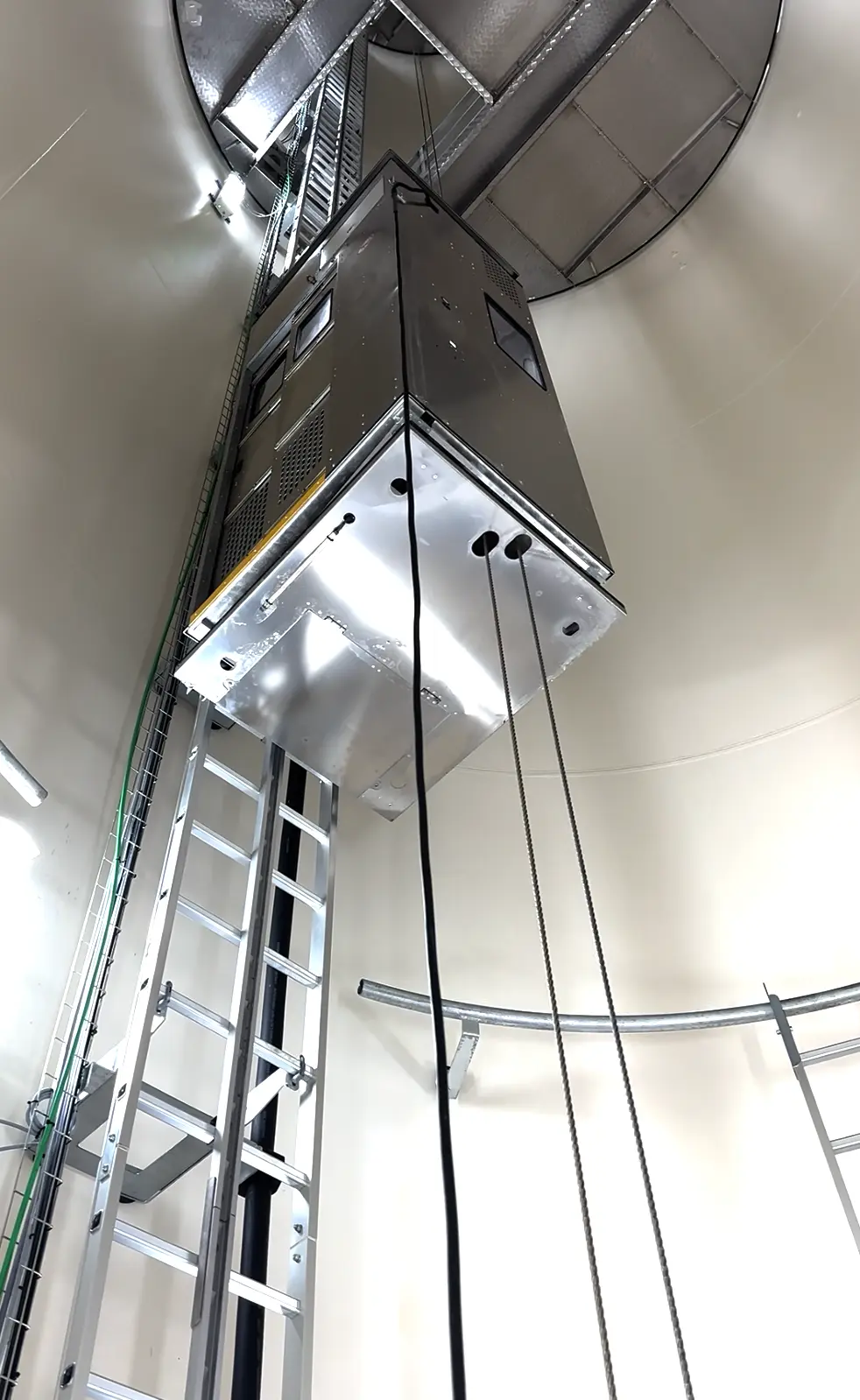

Elevadores de serviço guiados por corda

300 a 450 KG de capacidade de carga. Ciclo de trabalho alto para chegar até o topo. O padrão de mercado pelo melhor preço, baixa manutenção e equipado para 25 anos de vida útil na turbina eólica sem substituição ou reforma dos principais componentes.

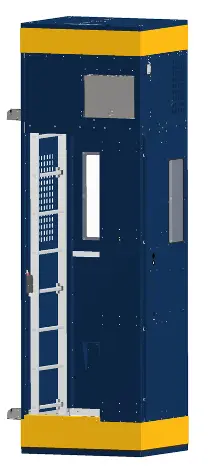

Elevadores de serviço guiados por escada

Operação estável durante o deslocamento, próximo à escada e com cruzamentos, para estar permanentemente pronto para uma evacuação. Carga de 300 KG e economia de espaço ao redor do poço, para cobrir toda a distância até o topo da torre.

Elevadores de serviço com acionamento por cremalheira e pinhão

Os elevadores de serviço ACADA com acionamento por cremalheira e pinhão são fundamentalmente operados por bateria. Disponíveis em vários tamanhos e com uma capacidade de carga de 300 KG a 600 KG, são adequados para transportar até 4 passageiros de forma rápida e segura durante a montagem crítica da torre.

Bester Preis, top Qualität, Made in Germany?

Möglich mit Acada!

Certificado de acordo com a EN 81-44

Nossos elevadores de serviço são certificados pela EN 81-44, e sempre desenvolvemos um conceito abrangente em colaboração com o cliente.

A torre inteira

O elevador de serviço é o ponto central dos Internos da Torre, mas não está sozinho. Em estreita coordenação com o cliente, sempre desenvolvemos um conceito abrangente e projetamos o acesso, incluindo conexões de escada, corrimãos, intertravamentos e planos de resgate.

APQP4Wind

Os projetos de engenharia da ACADA, incluindo o design de elevadores de serviço e internos de torres, são realizados de acordo com o padrão APQP4Wind, em estreita colaboração com clientes e partes interessadas do projeto. A qualidade e a segurança do processo são garantidas ao longo de toda a cadeia de suprimentos.

Foco no Cliente

Colocamos as necessidades de nossos clientes em foco. Sabemos que a aplicabilidade global dos produtos, a padronização global e a certificação desempenham um papel central.

Montagem final na Alemanha

Nossos elevadores de serviço de acordo com a EN81-44 são montados na Alemanha. Os principais componentes vêm da nossa produção na Índia - uma fábrica que é conhecida e certificada há anos por sua alta qualidade de fabricação. Com essa configuração, combinamos prazos de entrega curtos com logística econômica e pré-produção industrial em um nível de preço imbatível.

Graças a uma cadeia de suprimentos global perfeitamente ajustada e à montagem final na Alemanha, podemos geralmente entregar soluções em um curto espaço de tempo. Mesmo versões especiais ou adaptações personalizadas estão disponíveis mais rapidamente do que em outros fornecedores. Nossa cadeia de processos está completamente alinhada – desde o primeiro componente até o elevador finalizado.